What is a prism ballast? Embark on a journey into the world of lighting control as we delve into the intricacies of this enigmatic device. Its ability to regulate the flow of electricity in lighting systems has made it an indispensable component in various industries, from commercial spaces to residential homes.

Join us as we unravel the secrets of prism ballasts, exploring their types, applications, and the latest advancements in this fascinating field.

Prism ballasts, crafted from high-quality materials like iron and copper, play a crucial role in ensuring optimal lighting performance. They not only regulate the flow of electricity but also provide protection against voltage fluctuations and short circuits, ensuring the longevity of lighting fixtures.

Definition of Prism Ballast

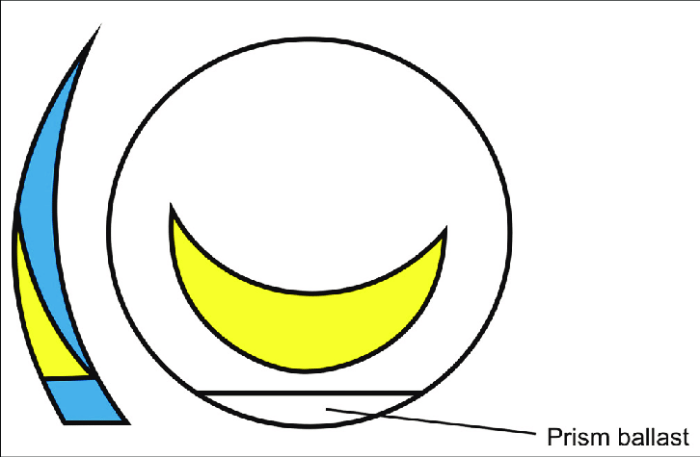

A prism ballast is a type of lighting system component that serves as a current-limiting device, regulating the flow of electricity to fluorescent lamps. Its primary purpose is to provide the necessary voltage and current to ignite and sustain the lamp’s operation.

Prism ballasts are typically used in commercial and industrial lighting applications where high-intensity and long-lasting illumination is required.Prism ballasts are typically constructed using magnetic materials, such as iron or steel, which are wound into a coil. This coil creates an inductive reactance that opposes the flow of alternating current (AC), effectively limiting the current that flows through the lamp.

The design of the prism ballast also includes a capacitor, which helps to improve the power factor of the system and reduce energy consumption.

Types of Prism Ballasts

Prism ballasts come in various types, each designed for specific applications and performance characteristics.

The main types of prism ballasts include:

Linear Prism Ballasts

Linear prism ballasts are designed for use with linear fluorescent lamps. They provide a constant current to the lamp, ensuring stable and efficient operation.

These ballasts are typically used in commercial and industrial settings, such as offices, warehouses, and factories.

Compact Prism Ballasts

Compact prism ballasts are designed for use with compact fluorescent lamps (CFLs). They are smaller in size compared to linear prism ballasts and are often used in residential and commercial applications.

These ballasts are known for their energy efficiency and are commonly used in recessed lighting fixtures and table lamps.

Electronic Prism Ballasts

Electronic prism ballasts use electronic circuitry to regulate the current supplied to the lamp. They are more efficient and offer better performance compared to traditional magnetic prism ballasts.

Electronic prism ballasts are widely used in both commercial and residential applications, providing longer lamp life and reduced energy consumption.

Applications of Prism Ballasts: What Is A Prism Ballast

Prism ballasts find extensive use in various industries and lighting scenarios. Their unique ability to regulate current and provide stable ignition makes them suitable for diverse applications.

Industrial Lighting

Prism ballasts are widely employed in industrial lighting systems. They ensure reliable operation of high-intensity discharge (HID) lamps, such as metal halide and high-pressure sodium lamps, commonly used in warehouses, factories, and outdoor lighting.

Commercial Lighting

In commercial settings, prism ballasts power HID lamps in retail stores, shopping malls, and office buildings. They provide efficient lighting with long lamp life and low maintenance costs.

Street Lighting

Prism ballasts are essential components in street lighting systems. They regulate the current flow to ensure optimal lamp performance and longevity, enhancing visibility and safety on roads and highways.

In the realm of optics, a prism ballast plays a crucial role in shaping and controlling light. Its design, utilizing a triangular prism, brings to mind the word “graph,” which conjures up a myriad of related terms like graphene , a wonder material with extraordinary properties.

The prism ballast, like its namesake, exhibits a geometric elegance that belies its profound impact on the world of optics.

Benefits of Prism Ballasts

* Improved lamp life and performance

- Reduced maintenance costs

- Enhanced energy efficiency

- Reliable ignition and stable operation

Drawbacks of Prism Ballasts, What is a prism ballast

* Higher initial cost compared to other ballast types

- Limited compatibility with certain lamp types

- Susceptibility to electromagnetic interference (EMI)

Real-World Examples

* The Empire State Building in New York City utilizes prism ballasts in its iconic lighting system.

- The Hong Kong International Airport employs prism ballasts to provide efficient and reliable lighting throughout its vast terminal complex.

- Major highways across the United States rely on prism ballasts to ensure safe and well-lit roadways.

Design and Construction of Prism Ballasts

Prism ballasts are engineered with specific principles to achieve their intended function. The design and construction process involves carefully selecting and assembling key components to ensure optimal performance and durability.

The primary components of a prism ballast include the core, windings, and enclosure. The core is typically made of laminated steel and serves as the magnetic circuit for the ballast. The windings, made of copper wire, are wound around the core and create the necessary magnetic field for ballast operation.

Manufacturing Process

The manufacturing process for prism ballasts typically involves the following steps:

- Core Assembly:Laminated steel sheets are stacked and pressed together to form the core.

- Winding:Copper wire is wound around the core to create the primary and secondary windings.

- Insulation:The windings are insulated to prevent electrical shorts.

- Encapsulation:The core and windings are encapsulated in a protective enclosure, which may be made of metal or plastic.

- Testing:The completed ballast undergoes rigorous testing to ensure it meets performance and safety standards.

Testing and Maintenance of Prism Ballasts

Prism ballasts play a crucial role in ensuring efficient lighting performance. To maintain their functionality and longevity, regular testing and maintenance are essential. This section discusses the methods used to evaluate the performance of prism ballasts and emphasizes the importance of proper maintenance practices.

Testing Prism Ballasts

Testing prism ballasts involves assessing their performance and efficiency. Common methods include:

- Performance Testing:This involves measuring the ballast’s output voltage, current, and power factor to ensure it meets the specified values.

- Efficiency Testing:Ballast efficiency is determined by measuring the ratio of the light output power to the input power. Higher efficiency indicates less energy loss.

Importance of Maintenance

Regular maintenance of prism ballasts is crucial for ensuring optimal performance and extending their lifespan. It includes:

- Visual Inspection:Periodically inspect the ballast for any physical damage, loose connections, or signs of overheating.

- Cleaning:Remove dust and debris from the ballast to prevent overheating and ensure proper cooling.

- Tightening Connections:Ensure all electrical connections are secure to prevent arcing or sparking.

Handling, Storage, and Disposal

Proper handling, storage, and disposal of prism ballasts are essential for safety and environmental protection. Guidelines include:

- Handling:Handle ballasts with care to avoid damage to internal components.

- Storage:Store ballasts in a dry, well-ventilated area away from direct sunlight.

- Disposal:Dispose of ballasts responsibly in accordance with local regulations. Some components may contain hazardous materials.

Future Trends in Prism Ballast Technology

The future of prism ballast technology holds promising advancements and innovations. As technology continues to evolve, prism ballasts are expected to become more efficient, reliable, and versatile.

One significant trend is the development of compact and lightweight prism ballasts. These ballasts are designed to minimize space requirements and reduce weight, making them ideal for applications where size and portability are critical. They are particularly useful in space-constrained environments, such as aerospace and underwater applications.

Energy Efficiency

Prism ballast technology is continuously evolving to improve energy efficiency. The development of high-frequency prism ballasts has significantly reduced energy losses compared to conventional low-frequency ballasts. These ballasts operate at higher frequencies, reducing core losses and increasing ballast efficiency.

Digital Control

The integration of digital control systems into prism ballasts is another emerging trend. Digital controllers provide precise control over ballast operation, allowing for optimized lamp performance and enhanced ballast functionality. They can monitor lamp parameters, adjust output power, and protect the ballast from faults, ensuring reliable and efficient operation.

Intelligent Ballasts

The future of prism ballast technology points towards intelligent ballasts that incorporate advanced sensing and communication capabilities. These ballasts can monitor their own performance, detect faults, and communicate with other devices in the lighting system. They can self-adjust to changing operating conditions, optimizing performance and extending ballast lifespan.

Common Queries

What are the benefits of using prism ballasts?

Prism ballasts offer numerous benefits, including voltage regulation, protection against short circuits, and improved energy efficiency. They also extend the lifespan of lighting fixtures and provide reliable and consistent lighting performance.

What are the different types of prism ballasts available?

Prism ballasts come in various types, including magnetic, electronic, and hybrid ballasts. Each type has its own unique characteristics and applications, catering to specific lighting requirements.

How do prism ballasts contribute to energy efficiency?

Prism ballasts play a vital role in energy efficiency by regulating the flow of electricity to lighting fixtures. They prevent over-voltage and under-voltage conditions, which can lead to energy wastage and reduced lifespan of lighting components.